Why Calibration & Ultra High Purity Gases Are Vital to Modern Industries

Introduction: The Invisible Force Behind Modern Industries

In today’s fast-paced industrial world, accuracy, reliability, and safety form the foundation of every successful operation. Whether it’s an oil refinery, pharmaceutical plant, or research laboratory, industries rely on Calibration Gases and Ultra High Purity (UHP) Gases to ensure smooth performance and reliable outcomes.

At Chemix Specialty Gases, we know that every >part per million (ppm) matters. Whether you’re testing emissions, calibrating sensors, or manufacturing semiconductors, the purity and precision of gases directly affect your results, efficiency, and compliance with global standards.

This article explains why calibration and ultra high purity gases are vital to modern industries, their key roles, and how Chemix ensures world-class gas quality and performance.

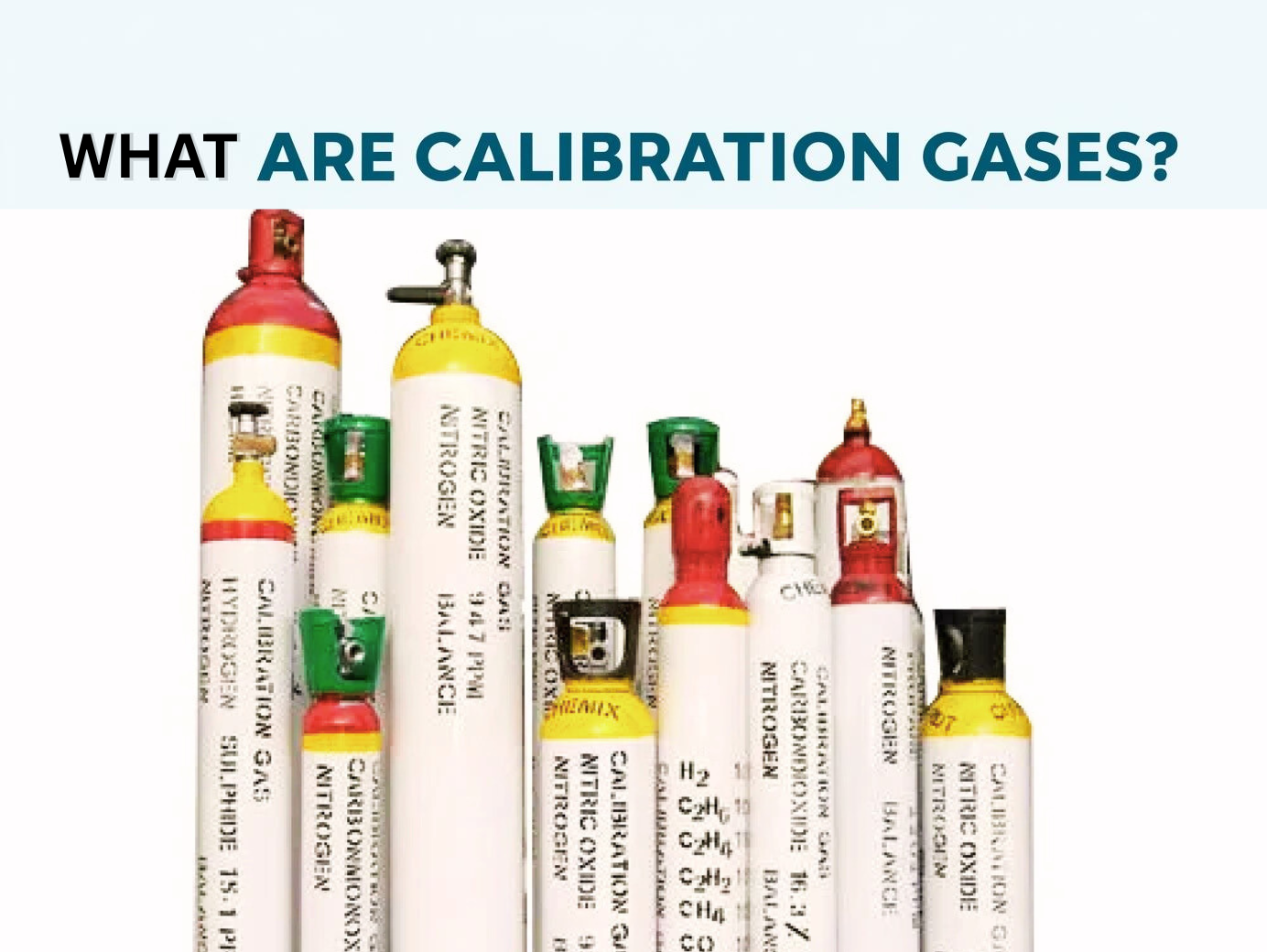

What Are Calibration Gases?

A Calibration Gas is a precisely prepared gas mixture used to verify and adjust the accuracy of gas detection instruments, analyzers, and monitoring devices. These gases serve as a reference standard that ensures your equipment provides correct and consistent readings.

Why Calibration Gases Matter

Imagine a gas detector showing slightly wrong data in a refinery or lab. A small inaccuracy could cause major safety issues or production errors. Calibration Gases eliminate this risk by ensuring your instruments remain accurate, stable, and traceable.

Common Calibration Gas Components

- Methane (CH₄)

- Carbon Monoxide (CO)

- Carbon Dioxide (CO₂)

- Nitrogen (N₂)

- Oxygen (O₂)

- Hydrogen Sulfide (H₂S)

- Ethylene (C₂H₄)

Each gas mixture is prepared in controlled conditions with certified accuracy, ensuring compliance with ISO, NABL, and industrial safety standards

What Are Ultra High Purity (UHP) Gases?

Ultra High Purity Gases are gases with 99.999% (5.0 grade) or higher purity. These gases contain almost no trace contaminants like moisture, oxygen, or hydrocarbons — which can impact analysis accuracy or product quality.

Examples of UHP Gases

- UHP Nitrogen (N₂)UHP Nitrogen (N₂) – Used for blanketing, purging, and as a carrier gas in chromatography

- UHP Argon (Ar) – Essential for welding, metallurgy, and semiconductor processing

- UHP Helium (He) – Common carrier gas for GC analysis and leak detection

- UHP Hydrogen (H₂) – Used in fuel cells, chemical reduction, and refining

- UHP Oxygen (O₂) – Supports combustion, healthcare, and research applications

Even a minor impurity can cause instrument drift, contaminated reactions, or failed experiments. That’s why UHP Gases are the hidden champions behind innovation and industrial precision.

Purity and Precision: The Perfect Combination

Every modern industry depends on purity and calibration. Without the right gas quality and standardized mixtures, your readings and product consistency are at risk.

| Parameter | Role of Calibration Gas | Role of UHP Gas |

|---|---|---|

| Accuracy | Calibrates detectors & sensors | Ensures pure test environment |

| Safety | Prevents false alarms | Maintains process stability |

| Compliance | Meets ISO & industry standards | Enables traceable results |

| Quality | Validates product integrity | Prevents contamination |

When both Calibration Gases and UHP Gases work together, industries achieve maximum efficiency, safety, and compliance.

Applications of Calibration & Ultra High Purity Gases

Let’s explore how different industries depend on these gases daily:

1. Oil & Gas Industry:

The oil and gas sector uses Calibration Gas Mixtures for gas detection systems, leak testing, and emission monitoring. UHP Gases like Nitrogen and Helium are used for pipeline purging and pressure testing

Example : Refineries use H₂S and CH₄ calibration mixtures daily to verify detectors and protect worker safety

2. Pharmaceuticals & Biotechnology

In the pharmaceutical industry, purity equals precision. UHP Gases are used in chromatography, sterilization, and drug manufacturing to maintain accurate results and avoid contamination.

Example : UHP Nitrogen creates an inert atmosphere during drug packaging, preventing oxidation and ensuring long shelf life.

3. Environmental Monitoring

Environmental labs rely on Calibration Gases for air quality analyzers, pollution control sensors, and stack emission tests. These gases ensure compliance with CPCB and ISO 17025 standards.

Example : A CO₂ analyzer calibrated with certified Calibration Gas provides precise readings for emission reporting.

4. Chemical & Manufacturing Plants

Manufacturing processes involving combustion control, gas chromatography, or reaction testing depend on UHP Gases and Calibration Gases for accurate control and safety.

Example : UHP Oxygen supports cleaner combustion and higher product yield in chemical production.

5. Semiconductor & Electronics

In semiconductor fabrication, even trace impurities can ruin microchips. UHP Argon, Nitrogen, and Hydrogen maintain an inert, contamination-free environment for wafer processing.

Example : UHP Argon ensures oxygen-free plasma etching, critical for chip manufacturing.

6. Healthcare & Medical Devices

From anesthesia machines to blood gas analyzers, Calibration and UHP Gases ensure medical equipment works with precision and safety.

Example :Hospitals use O₂ and CO₂ calibration gases to maintain the accuracy of respiratory analyzers.

7. Research & Development Laboratories

Research labs depend on traceable Calibration Standards and UHP Gases to maintain experiment reliability and reproducibility.

Example : UHP Helium is the preferred carrier gas for high-resolution chromatography in analytical labs.

The Chemix Edge: Purity, Precision & Performance

At Chemix Specialty Gases, we are not just an Industrial Gas Supplier — we are a quality partner trusted by industries across India. Every gas cylinder undergoes stringent testing, certification, and leak integrity checks before dispatch.

Why Chemix Is Trusted by Leading Industries

- ✅ Custom Calibration Gas Mixtures for any required concentration

- ✅ ISO & NABL Certified Blending Facility

- ✅ High-Quality Cylinder Packaging & Valving Systems

- ✅ Nationwide On-Time Delivery

- ✅ Dedicated Technical Support Team

Our advanced gas blending systems and analytical instruments ensure every batch meets exact specifications with traceable accuracy.

Quality Assurance & Certification

Chemix follows rigorous Quality Assurance (QA) and Quality Control (QC) processes at every step:

- ISO-compliant preparation and testing

- Gas Chromatography (GC) and Mass Spectrometry validation

- Moisture and impurity detection

- Batch certification with composition reports

- Cylinder pressure and leak testing

These quality measures ensure that Chemix Specialty Gases deliver Calibration Gas Mixtures and UHP Gases that meet international standards for reliability and performance.

What Happens When You Don’t Use Calibrated or Pure Gases?

Neglecting gas calibration or using low-purity gases may appear cost-effective at first, but the long-term risks are serious:

- ❌ Inaccurate Data → Wrong readings, poor decisions

- ❌ Safety Risks → False alarms or missed leaks

- ❌ Product Failure → Contamination during manufacturing

- ❌ Equipment Damage → Impurities corrode sensitive instruments

- ❌ Regulatory Issues → Non-compliance during audits

Using Certified Calibration Gases and UHP Gases ensures your equipment and operations stay safe, compliant, and efficient.

Sustainability & Environmental Commitment

At Chemix, we are committed to eco-friendly practices — optimizing gas production, reducing waste, and following safe cylinder disposal protocols. Our gases help industries reduce carbon emissions, improve process efficiency, and support ESG (Environmental, Social, Governance) goals.

Nationwide Delivery – Reliable & On-Time

With a strong logistics network, Chemix Specialty Gases delivers cylinders safely and efficiently across India — including Bangalore, Mumbai, Hyderabad, Delhi,and beyond.

Every cylinder — from Calibration Gas Mixtures to Ultra High Purity Gases — is dispatched with proper labeling, documentation, and NABL-traceable certification for complete reliability.

Expertise You Can Trust

Chemix follows the principle to build credibility and customer confidence:

- 🧪 Experience: Years of expertise in gas manufacturing and analysis

- 🎓Expertise: Skilled chemists and engineers ensuring accuracy

- 📜 Authoritativeness: Recognized supplier for major R&D and industrial clients

- 🤝 Trust: Transparent quality reports and customer-first service

Why Choose Chemix Specialty Gases?

- 🌟 Precision-blended Calibration Gas Mixtures

- 💎 Reliable Ultra High Purity Gas Supply

- 🧾 NABL-Traceable Certificates for Every Cylinder

- 🚛 On-Time Nationwide Dispatch

- 👷 Expert Technical Assistance

- 🔬 Serving Laboratories, Refineries, Pharma, Food & Research Sectors

At Chemix Specialty Gases, every cylinder represents quality, trust, and commitment to excellence.

Conclusion: Purity + Calibration = Industrial Accuracy

In modern industries, “Accuracy begins with purity.” Every reading, every process, and every product relies on the quality of gases behind the scenes.

That’s why top industries choose Chemix Specialty Gases — to ensure safe, accurate, and reliable operations through Calibration Gas Mixtures and Ultra High Purity Gases.

Whether you’re in refining, manufacturing, or research, remember — the purity of your gas defines the purity of your results.

Frequently Asked Questions (FAQs)

1. What makes calibration gases essential for industrial accuracy?

Calibration gases help verify and adjust gas detection and analytical instruments, ensuring accurate readings and maintaining consistent industrial process performance.

2. Why are ultra-high purity gases important for modern industries?

Ultra-high purity gases reduce contamination, increase precision, and support critical applications in laboratories, pharmaceuticals, electronics, and environmental monitoring.

3. How do calibration gases improve safety in industrial environments?

Regular calibration with certified gas mixtures prevents false alarms, ensures equipment reliability, and helps industries comply with strict safety and environmental regulations.

4. What industries rely heavily on calibration and high-purity gases?

Sectors like oil & gas, chemical manufacturing, food & beverage, healthcare, and semiconductor production depend on high-purity and calibration gases for accurate measurements and quality control.

5. How often should gas detection instruments be calibrated using calibration gases?

Most industries perform routine calibration weekly, monthly, or as per manufacturer guidelines to maintain accurate, stable, and reliable equipment performance.

5. Why is the demand for calibration gases increasing across various sectors?

With stricter safety regulations, advanced manufacturing processes, and rising quality control needs, industries increasingly rely on certified calibration gases.

6. What industries commonly use calibration and ultra high purity gases?

Major industries include oil & gas, pharmaceuticals, chemical manufacturing, food & beverage, environmental monitoring, electronics, and healthcare.

7. How often should calibration gases be used to maintain instrument accuracy?

Calibration frequency depends on the device and industry guidelines, but routine calibration—weekly, monthly, or before critical tests—is essential for accurate readings.

8. What happens if calibration gases are not used correctly?

Incorrect usage can lead to inaccurate measurements, compromised safety systems, production errors, and non-compliance with regulatory requirements.

9. Why is the purity level of gases critical for sensitive applications?

Even tiny impurities can impact research results, damage sensitive equipment, or alter chemical reactions, making ultra high purity gases essential.

10. Where can industries source reliable calibration and ultra high purity gases in India?

Trusted manufacturers like Chemix Specialty Gases provide certified calibration gases and ultra high purity gases with high accuracy, nationwide delivery, and industry-standard quality assurance.